- Home

- >

- News

- >

- What is paint paper ?

- >

What is paint paper ?

2023-11-15 17:00

What is paint paper?

Melamine paper has high brittleness and cannot curl, which affects its application in certain special fields. However, paint paper, with its good curling ability, forms a complementary effect to a certain extent. What is paint paper ? How does the painting paper produce? What is the finishing technology of Paint Paper and how many types of paint paper have ?

01 Development of Paint Paper

Painted paper originated from abroad and was produced by Perstorp Company in Sweden in the 1970s. The surface is mainly coated with polycarboxylic paint, nitrocellulose paint, and alkyd paint, and the production process is complex. The product performance cannot meet the needs of artificial board surface performance (such as hardness, pollution resistance, etc.), so this type of paper developed slowly in the early stages.

By the 1990s, the production technology of paint paper had developed rapidly in Europe and North America, and was also applied in China. This type of paper has a beautiful appearance, realistic texture, soft luster, warm touch, wear resistance, pollution resistance, easy bending, and elasticity, suitable for various shapes, opening up greater space for furniture design and utilization of artificial boards.

Moreover, due to the fact that paint paper has the final surface to be coated, it simplifies the furniture production process, improves production efficiency, and occupies a certain market share in the artificial board surface decoration market.

02: Production of paint paper

Compared to melamine impregnated adhesive film paper, there are differences in the manufacturing and use of paint paper, mainly including the pre impregnation/pre impregnation stage, printing coating stage, and roll covering stage.

(1) Pre impregnation/pre impregnation stage

The purpose of pre impregnation adhesive is to fill the pores in the sealed base paper and increase the tensile strength of the base paper so that the coating can be applied flat on its surface. Usually, acrylic amino resin is used, and the impregnation amount is generally 20%~25% of the base paper quantity. In addition, some paint papers will add a small amount of melamine formaldehyde resin 6 to increase the bonding strength and hardness within the paper layer. After soaking, hot air drying is required, with a drying temperature of 120-150C and a drying time of 40-60s.

(2) Printing and finishing stage

The printing and coating of this stage are completed on a single production line, with a production speed typically ranging from 80 to 150m/min. During the printing stage, a layer of water-based ink is coated with silver using gravure printing equipment, and then dried by hot air at 60-100C. During the coating stage, it is usually applied twice, with a dosage of 1-8g/m each time. Coatings include water-based coatings, oil-based coatings, and electron beam cured coatings (EB coatings). After coating, the paint paper is made by drying with hot air at 80-150C or curing with electron beam, and then being rolled up. Plain painted paper does not need to go through the ink printing process

(3) Overlay stage

This stage is completed on a separate winding machine, with a winding speed typically of 150-200m/min. The paint paper that has been printed and coated before being rolled up has low flatness and inconsistent dimensions. It needs to be covered to improve the flatness of the paper roll and facilitate transportation. At the same time, the paint paper can be cut into the required length and width according to customer requirements, and a small amount of leftover materials will be generated. The coated paint paper will be packaged and stored in the warehouse according to packaging requirements

04 Finishing Technology of Paint Paper

Painted paper veneer artificial board can be divided into three types: flat pressing method, wrapping method, and online veneer method.

The flat pressing method usually uses polyvinyl acetate as the adhesive, which is applied to the surface of the artificial board substrate, and then the paint paper is laid flat on the surface of the artificial board, using a cold pressing veneer. The flat pressing method requires a high level of flatness for the substrate of artificial boards, as well as a flat and smooth surface of paint paper with high stiffness and hardness.

The coating method usually uses polyvinyl acetate as the adhesive, which is brushed onto the surface of the substrate and applied with cold pressing. The wrapping method is the most commonly used method for paint paper, which can be used for surface decoration of lines and shaped artificial boards. It has less requirements for the substrate, but requires paint paper to be soft, elastic, and free from creases.

05 Main classification of paint paper

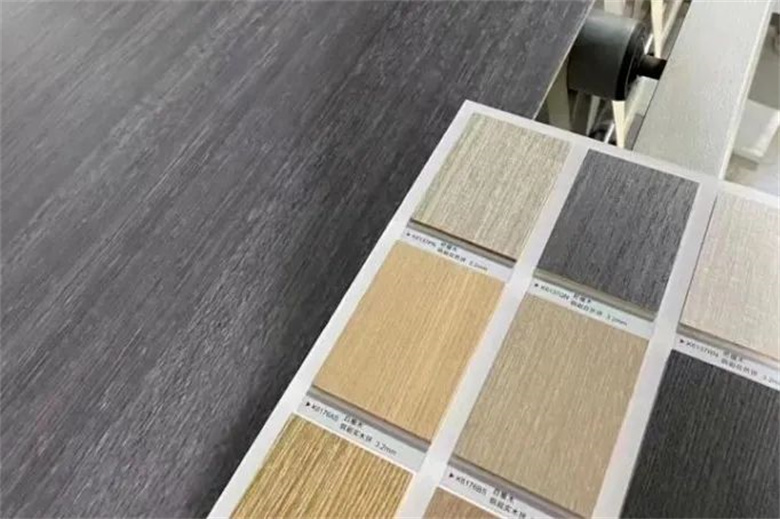

Paint paper can be divided into three types based on the type of surface coating: water-based paint paper, oil-based paint paper, and EB cured paint paper.

(1) Oil based paint paper

Oil based paint paper is printed or not printed on pre impregnated decorative base paper, coated with oil based paint, and dried by hot air. Oil based paint paper is currently the most widely used type of paint paper. Developed countries often use oil based coatings to produce paint paper. Its production technology is relatively mature, and the product quality is stable. The surface resistance to pollution, scratch, and solvent is higher than that of water-based paint paper. It can be used in places with relatively high surface quality requirements such as panel furniture, floor skirting, wall panels, bathroom cabinets, cabinet doors, and handicrafts.

(2) Water-based paint paper

Water-based paint paper is printed with or without water-based ink on pre impregnated decorative base paper. After coating with water-based paint, it is dried by hot air and made into a water-based paint. It is usually a mixture of water-based polyacrylic acid and amino resin, with a solid content of about 30% and a coating amount of 3-15/m. This type of coating has problems such as slow drying speed, low glossiness, poor water and solvent resistance when used as a solvent.

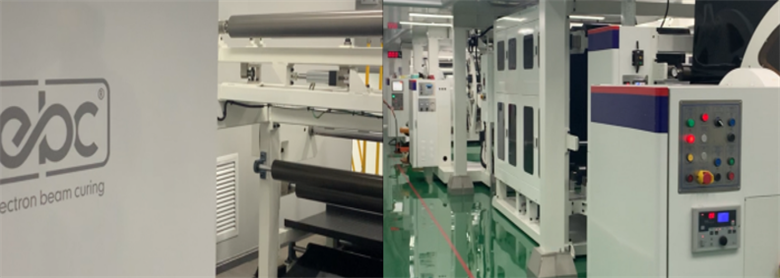

(3) EB cured paint paper

EB cured paint paper is printed or not printed on pre impregnated decorative base paper, coated with EB coating, and then cured by electron beam. Due to the strong penetrating power of the electron beam, which can reach a depth of 100um and provide sufficient electron concentration to crosslink the prepolymer in a short period of time, this type of paint paper does not add photoinitiators, which can avoid the migration and volatilization of residual photoinitiators and decomposition products, resulting in unpleasant odors, and has excellent environmental performance.

The surface coating of EB cured paint paper is completely cured, and the advantages of EB SINAI paper include yellowing resistance, sun resistance, stain resistance, easy cleaning, high scratch resistance, friction hardness, oil resistance, and chemical resistance,anti fingerprint . But it is necessary to install or separately configure electron beam curing equipment on the printing machine.

The EB SINAI paper produced by Zhihua Group , welcome yours inquire!