Substrate board and Its Advantages / Disadvantages

2023-09-08 15:30

Substrate board and Its Advantages / Disadvantages

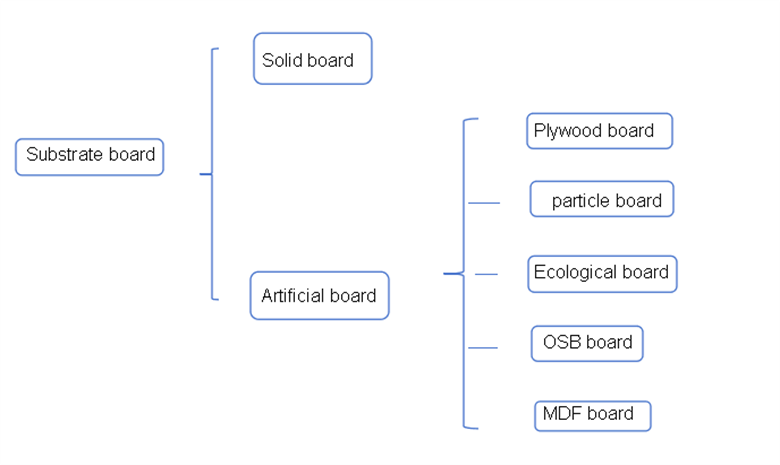

The commonly used substrate boards in whole house customization/home decoration include solid wood boards, plywood boards, particle boards, ecological boards, OSB boards, MDF board, etc.

The commonly used types of board in the market are substrate and decorative panel, and according to substrate classification, they are divided into solid wood board and artificial board. So what are the types advantages and disadvantages of solid wood board and artificial board?

1.Solid wood board

Solid wood board: Simply put, it is a board cut from natural trees, so each solid wood board has a unique texture and color. Solid wood boards have a natural aesthetic and texture, and are also very durable. However, due to the limitations of natural materials, the size and shape of solid wood boards are relatively limited, and the price is relatively high.

2. Plywood board

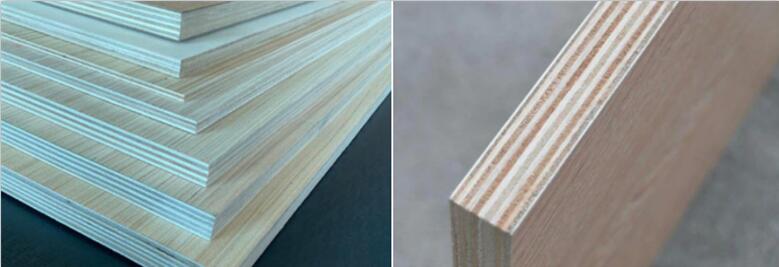

Plywood board: It is a board made by cross bonding multiple layers of wooden boards. Usually made by interlacing and pressing odd layers of thin wooden boards, where the grain directions of the adjacent two layers of boards are perpendicular or almost perpendicular. Simply put, it is glued together layer by layer with thin wooden boards.

Compared to solid wood boards, plywood boards have the following advantages: high strength, good stability, less deformation, light weight, strong durability, and relatively low price.

The disadvantage is that the surface of plywood boards is prone to moisture and damage, and their aesthetics are not as high as solid wood boards.

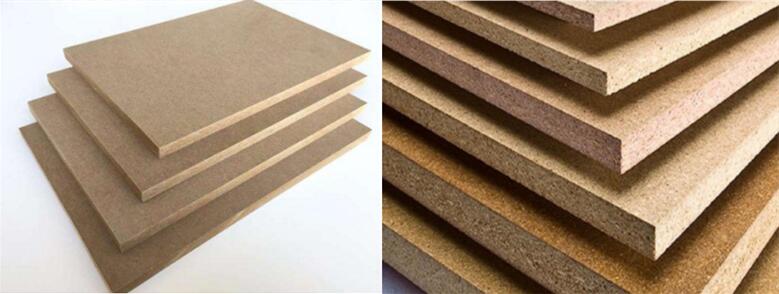

2. Particle board

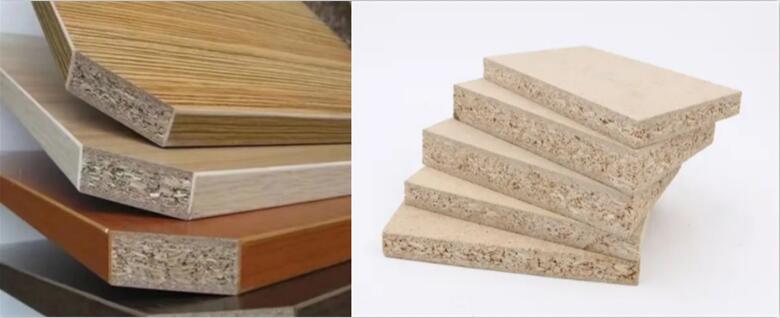

Particle board is also known as particle board. It is made by cutting wood into small particles, then mixing them with resin adhesive and compressing them into a board shape.

Advantages: Relatively low price: Compared to solid wood boards, particle boards have lower manufacturing costs, making them more affordable. Particle board has good load-bearing capacity and wear resistance. Due to its ability to manufacture large-sized boards, it is more suitable for making large furniture than solid boards.

Disadvantages: Relatively poor texture: Due to the fact that particle boards are made of small wood chips or chips, their texture is relatively poor and cannot be compared to solid wood boards. Inadequate moisture resistance: Particle boards usually cannot resist erosion in damp environments well, and long-term exposure to moisture may lead to deformation and damage. Difficult to repair: If the surface of the particle board is damaged, it may be difficult to repair and the entire board may need to be replaced. Possible presence of harmful substances such as formaldehyde: Some particle boards may contain harmful substances such as formaldehyde, and it is necessary to choose products with quality assurance.

3. Ecological board

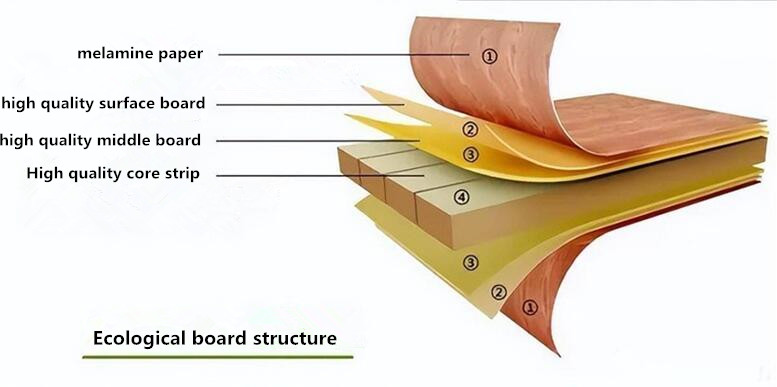

Ecological board: There are various names in the industry, commonly known as paintless board or melamine board. It is a decorative board made by soaking paper with different colors or textures in an ecological board resin adhesive, drying it to a certain degree of curing, and laying it on the surface of particleboard, moisture-proof board, medium density fiberboard, plywood, blockboard, or other hard fiberboard, after hot pressing.

Advantages of ecological boards

1. Environmental protection: Using environmentally friendly adhesives during the production process, coupled with high-temperature and high-pressure processes, releases residual formaldehyde, which is more environmentally friendly; And due to the surface finish, there is no need to repaint during use to avoid secondary pollution caused by the paint;

2. Convenience: Ecological boards can be processed on-site by carpenters, and there is no need to repaint when installing cabinets, which is very convenient;

3. Aesthetics: During the processing process, the surface of the ecological board is decorated with paper or wood veneer of different colors or textures, with rich and diverse patterns, which can meet people's different purchasing needs and match different living style characteristics;

4. Good performance: The ecological board has good stability and excellent flatness; The entire board is decorated with seamless melamine paper veneer and is equipped with a moisture-proof film to block moisture, effectively preventing water and moisture.

Disadvantages of ecological boards

Attention should be paid to the transportation and use of ecological boards. Once the surface finish is damaged, it is difficult to repair.

4. OSB board

OSB board and particle board both belong to particle board, and their differences lie in their structure and adhesive properties. The particle board is composed of small particles, which are finally arranged in a gradient structure or a cross arrangement of small particles on both sides of the large particles in the middle; The OSB board is an irregular geometric shape, with a longitudinal structure on the upper and lower surfaces, a transverse structure on the core layer, and a three-layer structure formed by hot pressing.

Generally speaking, European pine board has advantages such as strong stability, low deformation, and easy processing. However, due to being pressed from solid wood chips, its flatness performance is slightly poor.

5. MDF board

The full name is density fiberboard, which is a board made from wood fibers or other plant fibers as raw materials, prepared by fibers, applied with synthetic resin, and pressed under heating and pressure conditions. According to its density, it can be divided into high-density fiberboard, medium density fiberboard, and low-density fiberboard. The density range of medium density fiberboard is 650Kg/m ³—— 800Kg/m ³ Due to its uniform structure, fine material, stable performance, impact resistance, and easy processing, density board is widely used in domestic furniture, decoration, musical instruments, and packaging.

The surface of the MDF board is smooth and flat, the material is fine, the performance is stable, the edges are firm, and the decorative properties of the board surface are good. However, density board has poor moisture resistance, and in contrast, its grip on nails is poorer than particleboard. If the screws become loose after tightening, it is difficult to fix the density board again due to its low strength.

Please continue to pay attention, the next article will introduce five types of decorative panels!