UV Stability Chemical Resistance Easy To Cut Pvc Film

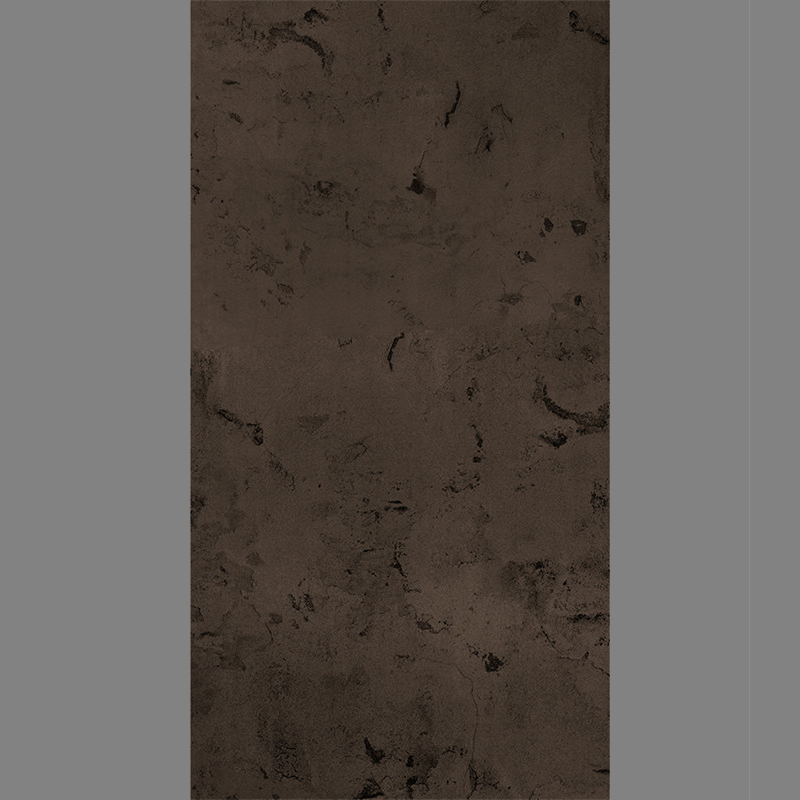

Item code : TAD-3008

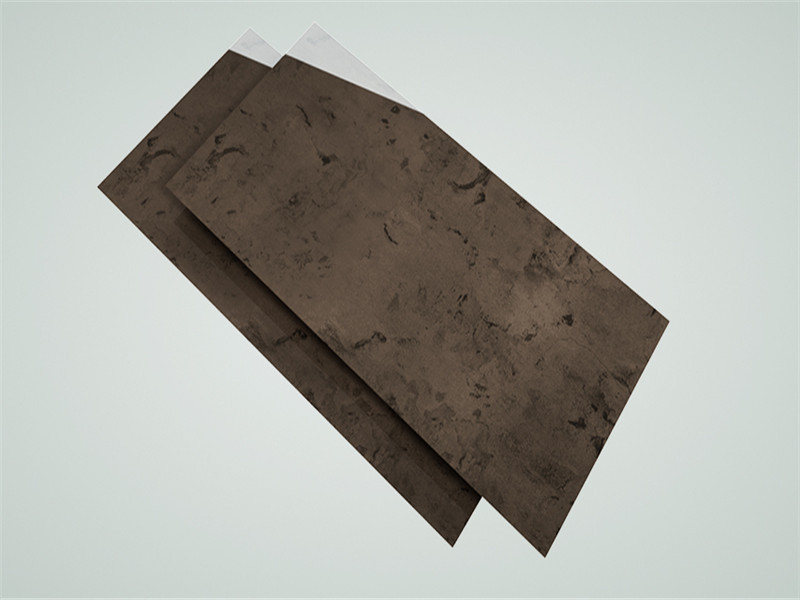

Dark Color Marble design PETG film/sheet is a kind of new Eco- friendly deco material ,it can be laminated onto MDF board, plywood board, particle wood board, aluminum honeycomb board, PVC foam board and other flat plates.

UV Stability Chemical Resistance Easy To Cut Pvc Film

PVC film is a versatile material that is known for its UV stability, chemical resistance, and ease of cutting. It is often used in applications where these properties are important, such as in greenhouses, signage, and medical devices.

UV stability is the ability of a material to resist the degradation caused by ultraviolet (UV) light. UV light can cause plastics to become brittle and discolored. PVC film is typically made with additives that protect it from UV light, making it a good choice for applications where it will be exposed to sunlight.

Chemical resistance is the ability of a material to resist the attack of chemicals. PVC film is resistant to a wide range of chemicals, including acids, bases, and solvents. This makes it a good choice for applications where it will come into contact with chemicals, such as in food processing and chemical manufacturing.

Ease of cutting is the ability of a material to be cut easily with a sharp blade. PVC film is easy to cut with a sharp blade, making it a good choice for applications where it will need to be cut to size.

Some of the most common uses for UV stable, chemically resistant, and easy-to-cut PVC film include:

Greenhouses: PVC film is often used as a covering for greenhouses because it is UV stable and allows light to pass through.

Signage: PVC film is a popular material for making signs because it is durable and can be printed with a variety of inks.

Medical devices: PVC film is used in some medical devices because it is chemically resistant and can be sterilized.

Electrical insulation: PVC film is used as an electrical insulator because it is non-conductive.

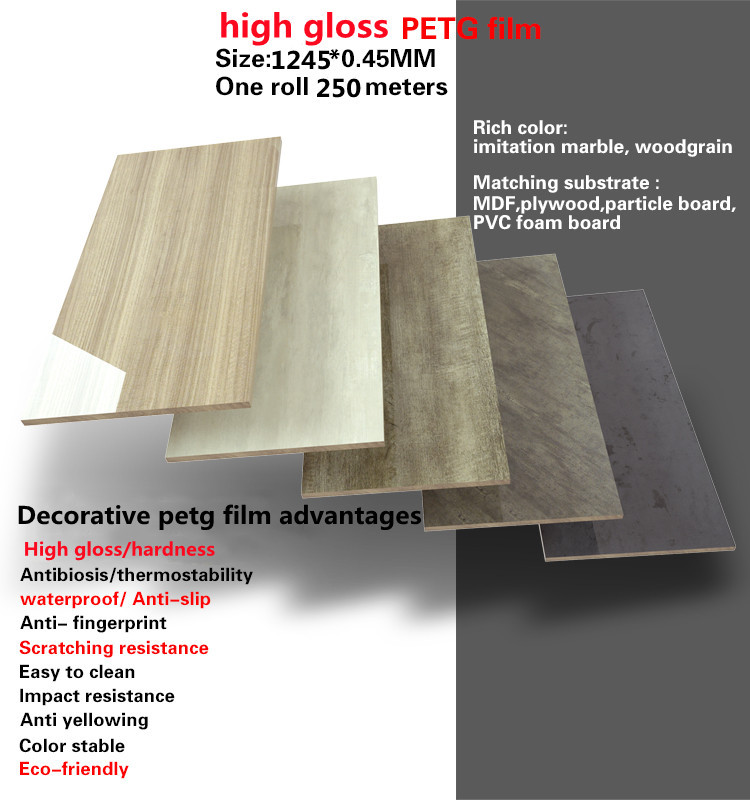

Pattern Design PETG Film is PVC + Transparent petg film , with many advantages:

color stability, high hardness, super wear-resistant, anti-scratch, anti yellowing , anti-fingerprint, Eco-friendly, heat resistance, resistance Pollution and burning resistance.

Pattern deesign PETG film surface coating technology : can be treated by excimer technology coating or EB coating technology .

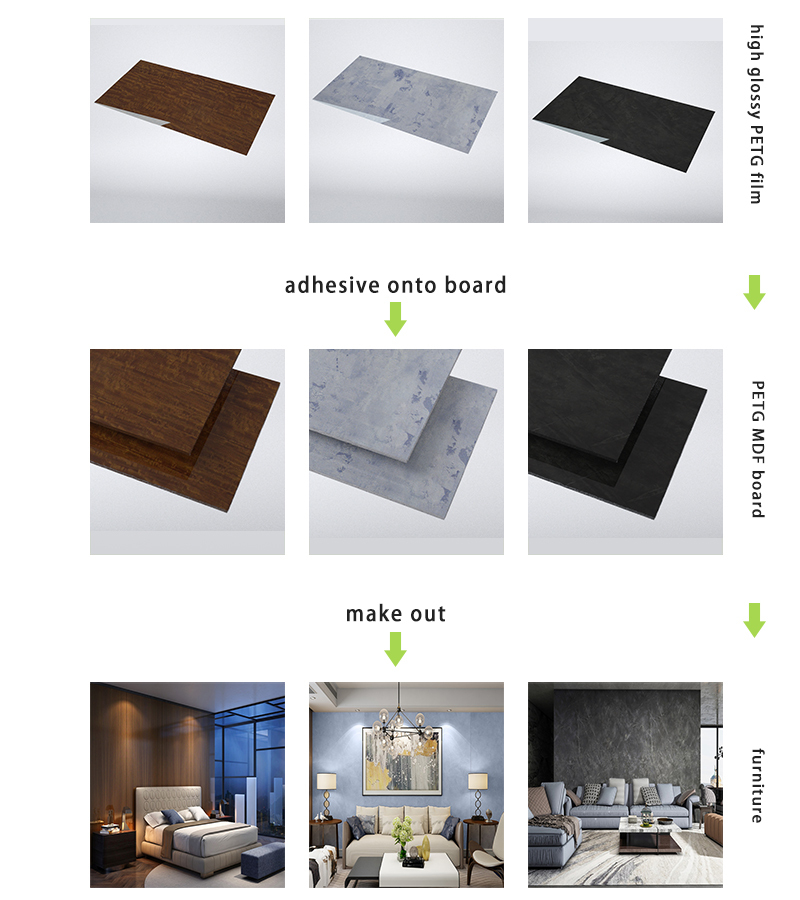

How process the PETG sheet onto substrate board : Using PUR laminte machine line laminte the sheet onto substrate board.

Pattern design PETG sheet application: cabinet door panel, wardrobe door panel, bathroom cabinet, wall panel, ecological door, office furniture, commercial space,ETC.